57YD09 NEMA 23, 1.8 Degree, 56mm size high torque gear reducer stepper motor DS-57YD09

Payment Type: L/C,T/T,Paypal,Western Union

Incoterm: FOB,CFR,CIF

Min. Order: 1 Set/Sets

Delivery Time: 7 Days

57YD09 NEMA 23, 1.8 Degree, 56mm size high torque gear reducer stepper motor DS-57YD09

Basic Info

Model No.DS-57YD09

Condition: New

Certification: CE, Other

Application Place: Factory

Applicable Thickness: Thick Material

Drive: Electric

Thread Number: Double Threads

Needle Number: Single Needle

Stitch Type: Lock Type

Additional Info

Packaging: Wooden Case Packing

Productivity: 600 Pairs

Brand: DGSF

Transportation: Ocean,Land,Air

Place of Origin: China

Supply Ability: 100 SETS PER MONTH

Certificate: CE

HS Code: 84522900.00

Port: Shenzhen,Guangzhou

Product Description

Hybrid stepping motor combines the advantages of reactive type and permanent magnet type. Its stator has multi-phase windings. The permanent magnet material is used on the rotor. There are many small teeth on the rotor and stator to improve the step moment accuracy. Its characteristics are large output torque, good dynamic performance and small step angle, but its structure is complex and its cost is relatively high.

According to the stator windings, there are two-phase, three-phase and five-phase series. The most popular one is the two-phase hybrid stepping motor, which accounts for more than 97% of the market share. The reason is that it has a high performance-price ratio and good effect with subdivision driver. The basic step angle of the motor is 1.8 degree per step. With the first half step driver, the step angle is reduced to 0.9 degree. With the subdivision driver, the step angle can be subdivided up to 256 times (0.007 degree/micro step). Because of friction and manufacturing accuracy, the actual control accuracy is slightly lower. The same stepper motor can be equipped with different subdivision drivers to change the accuracy and effect.

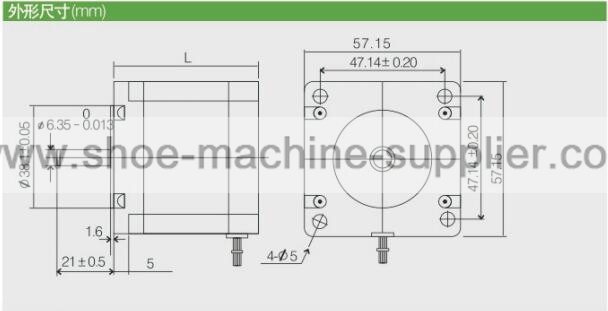

Product Specifications

| General specification | |

| Step accuracy | ±5%(full step, no load) |

| temperature rise | 80℃ Max |

| ambient temperature | -10℃—+50℃ |

| insulation resistance | 100MΩmin.500VDC |

| Withstand voltage | 500VAC for one minute |

| Radial runout | 0.06 Max.(450g-load) |

| Axial beating | 0.08 Max.(450g-load) |

| Model | Phase number | Stepping angle | Keeping Torque | Rated current | Phase inductance | Phase resistance | Number of leads | Rotor inertia | Positioning torque | Motor weight | Fuselage length L |

| 57YD09 | 2 | 1.8 | 0.9NM | 2.8 | 1.2mH | 0.8 | 8 | 260 | 0.4kg*cm | 0.6kg | 56mm |

| 57YD13 | 2 | 1.8 | 1.3NM | 2.8 | 2.1mH | 1.0 | 8 | 460 | 0.7kg*cm | 1.0kg | 76mm |

| 57YD13B | 2 | 1.8 | 1.3NM | 4.0 | 1.4mH | 1.0 | 4 | 460 | 0.7kg*cm | 0.7kg | 56mm |

| 57YD21A | 2 | 1.8 | 2.1NM | 5.0 | 1.8mH | 0.8 | 4 | 460 | 0.7kg*cm | 1.1kg | 77mm |

| 57YD22-A | 2 | 1.8 | 2.2Nm | 3.5 | 1.8mH | 0.8 | 8 | 460 | 0.7kg*cm | 1.1kg | 80mm |

| 57YD30 | 2 | 1.8 | 3.0Nm | 4.2 | 3.0mH | 0.7 | 4 | 680 | 1.0kg*cm | 1.5kg | 100mm |

Product Images

Our Main products

Our Factory

The related products